Start with the job the rifle must do. This overview compares length, chambering, material, how the rifling is made, profile, fluting, bore treatment, twist rate, gas system length, and muzzle threads. Define the purpose and the effective range first, then pick the shortest setup that still meets that goal. Keep this AR-15 barrel length guide by your side while you plan.

Barrel Length Fundamentals and What Changes With It

Length shapes how the rifle behaves. More inches usually add muzzle velocity and make the recoil pulse feel smoother. Fewer inches make the gun handier but raise blast at the muzzle and trim speed. Mechanical accuracy depends on barrel quality and proper installation; length mostly shifts practical accuracy by altering velocity, trajectory, and stability under load. On this platform, you will see barrels from about 7 to 24 inches, and 16 inches is the common civilian rifle length in the U.S., to avoid extra paperwork.

Start With Purpose and Effective Range

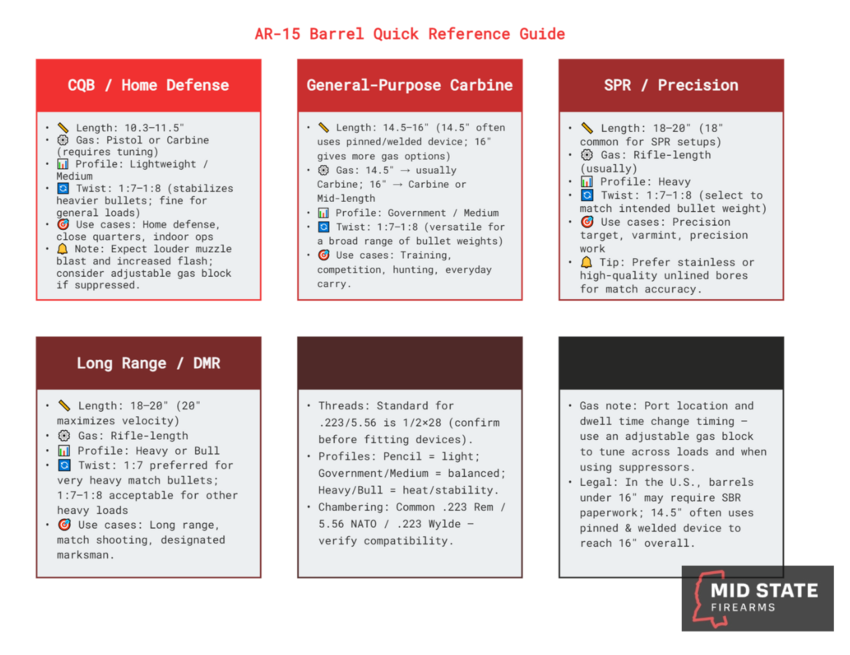

Choose the role before you choose parts. For home defense or close quarters, prioritize fast handling over peak speed. For a general-purpose carbine, look for a balanced feel that stays predictable at common distances. For longer shots, select a length that adds velocity and smooth cycling. When you scan options, review Barrels for AR-15 to see how lengths group by use. Set a minimum velocity for the load you plan to run and pick the shortest barrel that reaches it. An indoor build often fits 10.3 to 11.5 inches. A mixed-use rifle commonly lands at 16 inches. A precision or varmint setup benefits from 18 to 20 inches.

Typical AR-15 Barrel Length: Categories and Roles

Think in clear AR-15 barrel categories that map to real tasks.

Short and Maneuverable 10.3 to 11.5 inches

Built for tight spaces and quick transitions. Expect more blast and lower velocity. Plan gas tuning with any suppressor in mind.

Versatile Builds 14.5 inches and 16 inches

Sixteen inches offers a familiar balance of ballistics and handling. A 14.5-inch barrel often uses a pinned and welded device to meet overall rifle-length requirements in the U.S.

SPR or DMR Focus 18 inches

Pairs well with rifle-length gas for a precision-leaning build. You gain useful velocity for distance with less weight than a 20-inch setup.

Distance Focused 20 inches

Chosen to maximize speed from .223 and 5.56 at range. The trade-off is added length and weight. These roles align with common AR-15 barrel types used for extended distance work.

Regulatory Notes for the U.S.

Rifle barrels under 16 inches may be treated as short-barreled rifles and require additional steps. Check current federal, state, and local rules before you assemble a configuration. A 16-inch barrel, or a 14.5-inch barrel with a properly pinned and welded device that reaches 16 inches overall, keeps a standard rifle on simpler ground.

Chambering Compatibility: .223 Rem, 5.56 NATO, .223 Wylde

A 5.56 NATO chamber safely runs both 5.56 and .223 Remington. A .223 Rem chamber is for .223 only. The .223 Wylde chamber accepts both and can favor accuracy with .223 match bullets. Other calibers change optimal length and gas choice, so match those builds to the cartridge and distance you expect to shoot. When you choose a contour, consult AR-15 barrel profiles to align heat management and balance with your firing schedule.

Barrel Materials Compared: Stainless vs Chrome-Moly Vanadium

Stainless steel resists corrosion well, holds a clean bore, and offers consistent dimensions that favor precision work and careful load development. It is a strong choice for shooters who value predictable groups and easy maintenance over very high heat tolerance. Chrome-moly vanadium (CMV) prioritizes durability and long life under high round counts, especially when training includes rapid strings or frequent classes. Many builders choose CMV for hard-use rifles that will see varied weather and minimal cleaning between sessions. This section helps you match material to how you will run an AR-15 barrel.

Manufacturing Methods Compared: Cold Hammer Forged vs Button or Cut

Cold hammer forging compacts the steel around a mandrel, producing tough bores that handle sustained fire well and often show long service life, though cost is typically higher. Button and cut rifling are widely used, cost-effective, and fully capable of excellent accuracy when the maker controls tooling, stress relief, and final finish. If you expect heavy heat and rough schedules, CHF can be reassuring; if you plan for measured strings and precision goals, button or cut barrels can shine. Understanding these tradeoffs prevents overpaying for features your training will not use on AR-15 barrels.

Profiles and Contours for Heat Management and Balance

Profile controls how the rifle carries and how it holds zero as heat builds. Pencil or lightweight contours save ounces and feel lively, but they heat quickly and may show a faster point of impact shift during long strings. Government and medium contours add material where heat accumulates, improving stability without turning the front end into a burden. Heavy profiles absorb more heat and keep shots steadier in slow or sustained fire, at the cost of front weight that you will notice offhand. Choose a contour that fits your firing schedule and the role you actually shoot, then sanity check that choice against AR-15 barrel profiles. Grouping roles by contour also clarifies how you sort AR-15 barrel types.

Fluting Benefits and Trade-offs

Fluting removes material to reduce weight while increasing surface area for cooling, and it does this without changing barrel length. Real gains are modest: you save some ounces and get slightly faster heat shedding, but stiffness changes are small and depend on the original contour. Fluting costs more to machine, so decide whether the weight reduction matters in your positions and carry routine. Use fluting as a finishing decision after length and contour are set while you compare Barrels for AR-15.

Interior Treatments and Coatings

Chrome-Lined Bores

Chrome lining protects the bore from corrosion, simplifies cleaning, and supports a long service life during high-volume training. The process can add tiny variations that matter to top-end groups, but for practical use, the durability benefits often outweigh a small precision trade. Many duty builds pair chrome lining with a steady gas setup on an AR-15 barrel.

Nitride or QPQ Treatments

Nitride, often called QPQ, hardens the surface and adds strong wear and corrosion resistance with minimal dimensional change. It is a practical fit for general-purpose rifles that need easy upkeep and consistent performance over time. Many shooters also like its smooth feel during cleaning.

Unlined or Bare Stainless for Match Use

Leaving a quality stainless bore unlined can deliver excellent uniformity for slow, deliberate fire. The trade is simpler: you get potential precision gains, but you must clean more carefully and protect the steel from harsh environments. This path suits methodical shooters who track round counts and maintain logs.

Twist Rate and Bullet Weight Pairing

Twist rate describes how far the rifling takes to spin the bullet one full turn; for example, 1:7 means one turn in seven inches. Heavier, longer bullets need faster twists to stabilize, while light varmint bullets can run well in slower twists. Use these common pairings as a starting point:

- 1:12 to 1:14 for lighter varmint bullets

- 1:9 to 1:10 for mid-weight general-purpose bullets

- 1:7 to 1:8 for heavier match or longer-range bullets

Choose the twist around the bullet weight you will shoot most, then confirm on paper before locking your build. Correct twist selection is a core step when choosing AR-15 barrels.

Gas System Lengths and How To Pair Them

A gas system’s length determines where the port lives and how the action times. Pistol-length gas sits closest to the chamber and drives short barrels with a firm, early pulse. Carbine-length gas moves the port forward, giving compact and mid-size builds steadier timing. Mid-length gas stretches dwell time on 14.5-inch and 16-inch barrels and usually feels smoother on the shoulder. Rifle-length gas lives farthest forward on 18-inch and 20-inch setups and tends to cycle calmly through longer strings. Use this sequence as a practical anchor in an AR-15 barrel guide.

Pairings are predictable in real use. Barrels in the 10.3 to 11.5-inch range run well with pistol-length or carbine-length gas once tuned. Barrels at 14.5 to 16 inches typically pair with carbine-length or mid-length gas, depending on the recoil feel you prefer. Barrels at 18 to 20 inches are most often matched with rifle-length gas for a gentle impulse and consistent ejection. An adjustable gas block is a straightforward tool to correct over-gassing or under-gassing, and it helps when adding a suppressor while you learn how to choose an AR-15 barrel.

Muzzle Threads and Devices

Most .223 and 5.56 barrels cut 1/2×28 threads. A flash hider trims visible flash and preserves low-light vision. A brake or compensator redirects gas to reduce recoil and muzzle rise, often improving split times. A suppressor demands concentric threads, a square shoulder, and careful alignment to avoid strikes. A pinned-and-welded device on a 14.5-inch barrel can reach a 16-inch overall length and keeps you within familiar AR-15 barrel types for a rifle build.

Handguards and Accuracy: Free Float vs Drop-In

A free-float handguard does not touch the barrel, so sling tension, bipod load, or a firm grip is less likely to nudge the point of impact. It also gives continuous mounting space for accessories and helps with repeatable results across positions, which pairs well with thoughtful AR-15 barrel profiles.

A drop-in handguard uses the delta ring and a handguard cap, works with standard front-sight bases, and installs quickly with basic tools. It is a practical, budget-friendly route for simple builds on Barrels for AR-15.

Free-float: pros

- Better point-of-impact stability under load

- Long, continuous space for accessories

- Often lighter than older quad-rails of similar length

Free-float: cons

- Installation may require part removal and re-torque

- Higher cost than basic two-piece options

Drop-in: pros

- Fast, straightforward installation with standard parts

- Cost-effective for training rifles

Drop-in: cons

- Handguard pressure can shift the point of impact

- Less continuous space for accessories

Putting Specs Together for Real Use

Use this field checklist when matching roles to parts in an AR-15 barrel guide.

- General-purpose carbine: 16-inch length, government or medium profile, mid-length gas, 1:7 to 1:8 twist, nitride or chrome-lined bore.

- CQB or home defense: about 11.5-inch length, lightweight or medium profile, tuned pistol-length or carbine-length gas, 1:7 to 1:8 twist, durable lining; add an adjustable gas block with a suppressor.

- Precision or varmint: 18 to 20-inch length, heavier profile, rifle-length gas, twist matched to heavier bullets, stainless or high-quality unlined bore.

Key Takeaways for Quick Decisions

Set role and ammunition first, pick length second, then match gas system and profile, then select material and lining, and finish with the muzzle interface. Confirm compatibility, torque, and alignment so the barrel performs as designed while you refine how to choose an AR-15 barrel.

-300x300.jpeg)